| Items |

_9231_reduced.png)

1250-PL

Almasol® High Temperature Lubricant 1250

List Price QUOTE

|

1250-TUBE

Almasol® High Temperature Lubricant 1250

List Price QUOTE

|

1250-CST10

Almasol® High Temperature Lubricant 1250

List Price QUOTE

|

1250-QD

Almasol® High Temperature Lubricant 1250

List Price QUOTE

|

1250-DR

Almasol® High Temperature Lubricant 1250

List Price QUOTE

|

|

Description

|

N/A

Long-Lasting, Nonmelting Grease Provides Constant Protection for High-Temperature Bearing Applications

Bearings operating in or near heat-generating equipment are subject to temperatures that cause ordinary greases to melt and run, leaving critical bearing surfaces unprotected. Almasol® High Temperature Lubricant is designed to withstand high temperatures, staying in place to provide constant lubrication. It also resists oxidation and vaporization. By ensuring longer lubrication intervals and fewer bearing failures, Almasol High Temperature Lubricant helps contribute to increased production and a healthier bottom line.

|

|

Buy this LE Product!

|

N/A

Don't See Pricing? Register Today!

|

|

Available Container Size

|

N/A

Pail

|

N/A

Single Tube

|

N/A

10 Pack Tube

|

N/A

Quarter Drum

|

N/A

Drum

|

|

GHS Statement

|

N/A

FFor commercial and professional use only

|

N/A

For professional and commercial use only

|

N/A

For professional and commercial use only

|

N/A

For commercial and professional use only

|

N/A

For commercial and professional use only

|

|

Beneficial Qualities

|

N/A

Withstands High Temperatures- Heavy base oil and R & O additive formulation ensures extended bearing protection

- Won’t melt or run out of bearings

- Resists oxidation and vaporization

- 1251 (NLGI 1) offers easy pumpabilityin central lubrication systems

Provides Superior Protection- Reduces wear by minimizing metal-to-metal friction, even under heavy loads

- Protects metal from rust and corrosion

Provides Long-Lasting, Cost-Saving Service- Exhibits excellent mechanical stability

- Reduces lubricant consumption

- Extends lubrication intervals

- Reduces downtime associated with bearing failures and frequent regreasing

|

|

Available Grades

|

N/A

- NLGI 2 1/2 (1250)

- NLGI 1 (1251)

|

|

Proprietary Additives

|

N/A

LE’s proprietary additivesare used exclusively in LElubricants. Almasol HighTemperature Lubricantcontains Almasol.

Almasol® solid wear reducing additive is able to withstand extremely heavy loads, chemical attack andtemperatures up to 1,900°F(1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizesmetal-to-metal contact and the resulting friction, heat and wear.

|

|

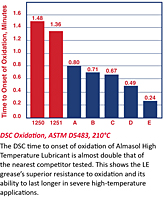

Differential Scanning Calorimetry

|

N/A

DSC is a sophisticated technique for evaluating the oxidation characteristics of a sample of lubricant in a static condition. It is a rapid and reproducible method that measures the heat flow under controlled conditions. Samples are put under pressure in a pure oxygen or air environment and the temperature raised until significant heat flow occurs. This heat flow indicates onset of oxidation. The longer the time taken for heat flow to occurindicates better resistance to oxidation and hence longer lubricant life in the application. Samples may also be run at a fixed temperature and timerecorded until onset of oxidation. While there is no exact correlation to field conditions, several minutes in the DSC represents several hundred hours in operation.

|

|

Performance Requirements Met or Exceeded

|

N/A

|

|

Recommendations

|

N/A

- Although this product is formulated with inorganic thickeners, it contains petroleum oil which, under very high temperatures, can ultimately form carbon and residues as do other greases with petroleum oils.

- May show high-starting torques due to heavy oil.

|

|

Typical Applications

|

N/A

High-temperature applications, including: asphalt plants,brick/ceramic kilns, exhaust fans, kiln car bearings, lime kilns, oven conveyors, pellet mills, plastics and soot blowers

|

|

Customer Testimonials

|

N/A

1250 & 1251 JD Heiskell

1250 Pirelli Cable Corp

1250 SGL Carbon Fibres

1251 Triangle Brick Co

|

|

Asset Reliability Solutions

|

N/A

Reliability Solution Products

|

|

Thickener Type

|

N/A

Inorganic

|

|

Texture

|

N/A

Smooth, Buttery

|

|

Color

|

N/A

Red

|

|

NLGI Grade

|

N/A

2 1/2

|

|

Worked 60 Penetration ASTM D217

|

N/A

250

|

|

Dropping Point ºC(ºF), ASTM D2265

|

N/A

None

|

|

Viscosity @ 100°C, cSt, ASTM D445

|

N/A

30.9

|

|

Viscosity @ 40°C, cSt, ASTM D445

|

N/A

495

|

|

Corrosion Prevention DI H2O, ASTM D1743

|

N/A

Pass

|

|

Corrosion Prevention Sea H2O, ASTM D5969

|

N/A

Pass

|

|

Corrosion Prevention Emcor, ASTM D6138

|

N/A

1 Max

|

|

Four-Ball EP Weld Point kgf, ASTM D2596

|

N/A

160

|

|

Four-Ball EP Load Wear Index kgf, ASTM D2596

|

N/A

33.1

|

|

Four-Ball Wear @ 75ºC, 1,200 rpm, 40 kgf, 60 minutes, mm wear, ASTM D2266

|

N/A

0.77

|

_9231_reduced.png)