| Items |

_9231_reduced.png) /Asset/Pail (grease)_9231_reduced.png /Asset/Pail (grease)_9231_reduced.png 1282-PL Monolec® Extend EM Grease 1282 List Price QUOTE

|

/Asset/1282.png /Asset/1282.png 1282-TUBE Monolec® Extend EM Grease 1282 List Price QUOTE

|

_ICE_9257_reduced.png) /Asset/Box (10 tubes)_ICE_9257_reduced.png /Asset/Box (10 tubes)_ICE_9257_reduced.png 1282-CST10 Monolec® Extend EM Grease 1282 List Price QUOTE

|

_ICE_9263_reduced.png) /Asset/Box (40 tubes)_ICE_9263_reduced.png /Asset/Box (40 tubes)_ICE_9263_reduced.png 1282-CST Monolec® Extend EM Grease 1282 List Price QUOTE

|

_9231_reduced.png) /Asset/Pail (grease)_9231_reduced.png /Asset/Pail (grease)_9231_reduced.png 3752-PL Almagard® Vari-Purpose Lubricant 3752 List Price QUOTE

|

|||||

| Buy this LE Product! | N/A Don't See Pricing? Register Today! | |||||||||

| Available Container Size | N/A Pail | N/A Single Tube | N/A 10 Pack Tube | N/A Case 40 Tubes | N/A Pail | |||||

| GHS Statement | N/A For professional and commercial use only | N/A For professional and commercial use only | N/A For professional and commercial use only | N/A For professional and commercial use only | N/A For commercial and professional use only | |||||

| Beneficial Qualities |

N/A

Enhances Performance & Reliability

|

N/A

Enhances Performance & Reliability

|

N/A

Enhances Performance & Reliability

|

N/A

Enhances Performance & Reliability

|

N/A

Withstands Pressure & Reduces Wear

|

|||||

| Available Grades | N/A | N/A | N/A | N/A |

N/A

|

|||||

| Proprietary Additives | N/A | N/A | N/A | N/A |

N/A

LE’s proprietary additives are used exclusively in LElubricants. Almagard Vari-Purpose Lubricant contains Almasol and Quinplex. Almasol® solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and temperatures up to 1,900°F (1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizes metal-to-metal contact and the resulting friction, heat and wear. Quinplex® impact-resistant additive contributes to outstanding water resistance, tackiness and enhanced mechanical stability, and helps to form a barrier against corrosion. |

|||||

| Performance Requirements Met or Exceeded | N/A | N/A | N/A | N/A |

N/A

|

|||||

| Typical Applications |

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

|||||

| Asset Reliability Solutions | N/A Reliability Solution Products | |||||||||

| Thickener Type | N/A Polyurea | N/A Polyurea | N/A Polyurea | N/A Polyurea | N/A Lithium Complex | |||||

| Texture | N/A Smooth w/ Slight String | N/A Smooth w/ Slight String | N/A Smooth w/ Slight String | N/A Smooth w/ Slight String | N/A Smooth w/Tack | |||||

| Color | N/A Purple | N/A Purple | N/A Purple | N/A Purple | N/A Red | |||||

| NLGI Grade | N/A 2 | N/A 2 | N/A 2 | N/A 2 | N/A | |||||

| Worked 60 Penetration ASTM D217 | N/A 275 | |||||||||

| Dropping Point ºC(ºF), ASTM D2265 | N/A 271 (520) | N/A 271 (520) | N/A 271 (520) | N/A 271 (520) | N/A 282 (540) | |||||

| Viscosity @ 100°C, cSt, ASTM D445 | N/A | |||||||||

| Viscosity @ 40°C, cSt, ASTM D445 | N/A | |||||||||

| Oxidation drop in psi @ 100 hrs, ASTM D942 | N/A 3 | N/A 3 | N/A 3 | N/A 3 | N/A 5 | |||||

| Corrosion Prevention DI H2O, ASTM D1743 | N/A Pass | |||||||||

| Operating Temperature* °C (°F) | N/A | |||||||||

| Operating Temperature* | N/A | |||||||||

| Water Spray-off % Loss, ASTM D4049 | N/A 10.0 | N/A 10.0 | N/A 10.0 | N/A 10.0 | N/A 8.6 typical / 20 max. | |||||

| Pour Point °C (°F), ASTM D97 | N/A | |||||||||

| Recommendations | N/A | |||||||||

| Flash Point °C (°F), (COC), ASTM D92 | N/A | |||||||||

| Water Wash-out @ 37.8°C (100°F), % loss, ASTM D1264 | N/A | |||||||||

| Viscosity @ 40°C, cSt, ASTM D445 (with Quinplex) | N/A | |||||||||

| Viscosity @ 40°C, cSt, ASTM D445 (without Quinplex) | N/A | |||||||||

| Viscosity @ 100°C, cSt, ASTM D445 (without Quinplex) | N/A | |||||||||

| Oxidation drop in psi @ 1,000 hrs, ASTM D942 | N/A | N/A | N/A | N/A | N/A 30 | |||||

| Oil Separation 30 hrs @ 100ºC, % bleed, ASTM D6184 | N/A <2.0 | N/A <2.0 | N/A <2.0 | N/A <2.0 | N/A | |||||

| Timken OK Load lbs, ASTM D2509 | N/A 50 | N/A 50 | N/A 50 | N/A 50 | N/A 70 | |||||

| Four-Ball EP Weld Point kgf, ASTM D2596 | N/A | |||||||||

| Four-Ball EP Load Wear Index kgf, ASTM D2596 | N/A | |||||||||

| Water Washout % loss, ASTM D1264 | N/A | |||||||||

| Wheel Bearing Leakage gram loss, ASTM D1263 | N/A | |||||||||

| Recommendation |

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

|||||

| Proprietary Additive |

N/A

LE's proprietary additive are used exclusively in LE lubricants. Monolec Extend EM Grease contains Monolec. Monolec® wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. An invaluable component in LE's engine oils, industrial oils and many of its other lubricants, Monolec allows opposing surfaces to slide by one another, greatly reducing friction, heat and wear. |

N/A

LE's proprietary additive are used exclusively in LE lubricants. Monolec Extend EM Grease contains Monolec. Monolec® wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. An invaluable component in LE's engine oils, industrial oils and many of its other lubricants, Monolec allows opposing surfaces to slide by one another, greatly reducing friction, heat and wear. |

N/A

LE's proprietary additive are used exclusively in LE lubricants. Monolec Extend EM Grease contains Monolec. Monolec® wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. An invaluable component in LE's engine oils, industrial oils and many of its other lubricants, Monolec allows opposing surfaces to slide by one another, greatly reducing friction, heat and wear. |

N/A

LE's proprietary additive are used exclusively in LE lubricants. Monolec Extend EM Grease contains Monolec. Monolec® wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. An invaluable component in LE's engine oils, industrial oils and many of its other lubricants, Monolec allows opposing surfaces to slide by one another, greatly reducing friction, heat and wear. |

N/A | |||||

| Worked 10K Penetration ASTM D217 | N/A 277 | N/A 277 | N/A 277 | N/A 277 | N/A | |||||

| Worked 100K Penetration ASTM D217 | N/A 299 | N/A 299 | N/A 299 | N/A 299 | N/A | |||||

| Viscosity @ 100°C, cSt, ASTM D445 | N/A 14.00 | N/A 14.00 | N/A 14.00 | N/A 14.00 | N/A 11.70 | |||||

| Viscosity @ 40°C, cSt, ASTM D445 | N/A 145.0 | N/A 145.0 | N/A 145.0 | N/A 145.0 | N/A 144.0 | |||||

| Four-Ball EP Weld Point kgf, ASTM D2596 | N/A 620 kgf | N/A 620 kgf | N/A 620 kgf | N/A 620 kgf | N/A | |||||

| Copper Corrosion 24 hrs @ 100ºC, ASTM D4048 | N/A 1b | N/A 1b | N/A 1b | N/A 1b | N/A | |||||

| Evaporation 22 hrs @ 100ºC, % loss, ASTM D972 | N/A < 1.0 | N/A < 1.0 | N/A < 1.0 | N/A < 1.0 | N/A | |||||

| Grease Mobility 100 psi @ -18ºC (0ºF), USX Mobility procedure | N/A 0.039 gm/sec | N/A 0.039 gm/sec | N/A 0.039 gm/sec | N/A 0.039 gm/sec | N/A | |||||

| NLGI Grade | N/A | N/A | N/A | N/A | N/A 2 | |||||

| Flash Point ºC(ºF), ASTM D92 | N/A | |||||||||

| Corrosion Prevention 3% Sea H2O, ASTM D5969 | N/A | |||||||||

| EMCOR Rust Test DI H2O, ASTM D6138 | N/A | |||||||||

| Oil Separation 30 hrs @ 100ºC (212ºF), % Bleed, ASTM D6184 | N/A | |||||||||

| Timken OK Load lb, ASTM D2509 | N/A | |||||||||

| Four-ball EP Load Wear Index kgf, ASTM D2596 Weld Point, kgf | N/A | |||||||||

| Four-Ball Wear @ 75ºC (167ºF), 1,200 rpm, 40 kgf, 60 minutes, mm wear, ASTM D2266 | N/A | |||||||||

| Water Wash-out @ 80ºC (176ºF), % loss, ASTM D1264 | N/A | |||||||||

| Copper Corrosion 24 hrs @ 100ºC (212ºF), ASTM D4048 | N/A | |||||||||

| Available Grade | N/A | |||||||||

| Typical Industries | N/A | |||||||||

| Oxidation drop in psi @ 500 hrs, ASTM D942 | N/A | |||||||||

| Corrosion Prevention 5% Sea H2O, ASTM D5969 | N/A | |||||||||

| Four-Ball Wear @ 75ºC, 1,200 rpm, 40 kgf, 60 minutes, mm wear, ASTM D2266 | N/A | |||||||||

| Corrosion Prevention Sea H2O, ASTM D5969 | N/A | N/A | N/A | N/A | N/A Pass | |||||

| Oxidation by PDSC minutes @ 155°C, ASTM D5483 | N/A | |||||||||

| SRV-EP 50°C, 1 mm stroke, 50 Hz frequency, ball on disc, max load w/o seizure, N, ASTM D5706 | N/A | |||||||||

| Color | N/A | |||||||||

| Viscosity Index ASTM D2270 | N/A | |||||||||

| Corrosion Prevention 1% Sea H2O, ASTM D5969 | N/A | |||||||||

| Oil Separation 24 hrs @ 25ºC, 1.75 kPa (0.25 psi), % Bleed, ASTM D1742 | N/A | |||||||||

| Fretting Wear Protection, mg Loss (ASTM D4170) | N/A | |||||||||

| Low Temp Torque NM, ASTM D4693 | N/A | |||||||||

| Water Washout % Loss @ 80ºC, ASTM D1264 | N/A | |||||||||

| High Temperature Life hrs, ASTM D3527 | N/A | |||||||||

| Leakage Tendencies g, ASTM D4290 | N/A | |||||||||

| Elastomer Compatibility (ASTM D4289) | N/A | |||||||||

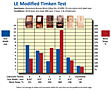

| LE Modified Timken Test |

N/A

|

|||||||||

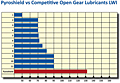

| Pyroshield vs Competitive Open Gear Lubricants LWI |

N/A

|

|||||||||

| NLGI Grade as Applied | N/A | |||||||||

| NLGI Grade in Service | N/A | |||||||||

| Note | N/A | |||||||||

| User Benefits | N/A | |||||||||

| What is MONOLEC®? | N/A | |||||||||

| Worked Penetration @ 77ºF (25ºC) | N/A | |||||||||

| Timken, ASTM D2509 | N/A | |||||||||

|

|

||||||||||