110 Scorpion Trail St, Diepsloot, 2189

Contact Number: (011) 464 1735

Email address: info@lubricationengineers.co.za

Automatic Lubrication System Delivers Right Amount of Lubricant at Right Time to Critical Equipment

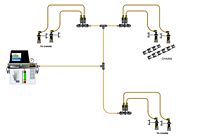

The Ovenworx™ Chain Spray/Brush System is an automatic lubrication system designed to dispense lubricants in small, measured amounts over short, frequent time intervals. It eliminates human resource constraints and makes consistent lubrication easier in physical locations or on types of machines where it was previously impossible. This innovative system comes in a spray or brush configuration.

Using an ALS for lubricant application leads to improved quality of lubrication as well as a reduction in labor requirements. Its successful use, however, requires knowledge of lubrication fundamentals. In order to avoid mistakes and realize positive results from such devices, you must select the right system for a given application, install the system correctly, and determine the optimum application rate. LE’s highly trained and skilled representatives can help you get started.

| Items |

LE-OVEN-CBN-6 Surefire with Controller 6 Brush List Price QUOTE

|

LE-OVEN-CBN-4 Surefire with Controller 4 Brush List Price QUOTE

|

||

| Beneficial Qualities |

N/A

Proper Lubrication

|

|||

| ALS Components |

N/A

|

|||

| 6 Spray | N/A ✓ - YES | N/A | ||

| 4 Spray | N/A | N/A ✓ - YES | ||

| Air/Oil Injection Lubrication System | N/A ✓ - YES | |||

| Copper Tubing | N/A ✓ - YES | |||

| Surefire with Controller | N/A ✓ - YES | |||

|

|

||||